Market

Brewery and Beverages

Clauger: Your Partner for a High-Performance and Sustainable Brewery

Breweries face significant challenges:

- Optimizing energy consumption: Beer production is energy-intensive. Breweries need to reduce their energy use to improve profitability and minimize their environmental impact.

- Limiting water consumption: Water is a key ingredient in beer. Breweries must optimize their water usage to conserve this essential resource.

- Reducing their environmental footprint: Breweries must minimize their impact on the environment by cutting CO2 emissions, waste, and water consumption.

Clauger is the ideal partner to help you optimize your industrial processes and reduce your environmental footprint, thanks to the expertise of our teams specializing in industrial refrigeration, air treatment, and energy efficiency.

Our commitments

Consume less energy, precisely tailored to your needs

A dual expertise in refrigeration and air treatment

Digital innovation at the heart of your decisions

Optimize your utilities to consume less energy across the brewery

Clauger offers various solutions to support you in managing your energy needs.

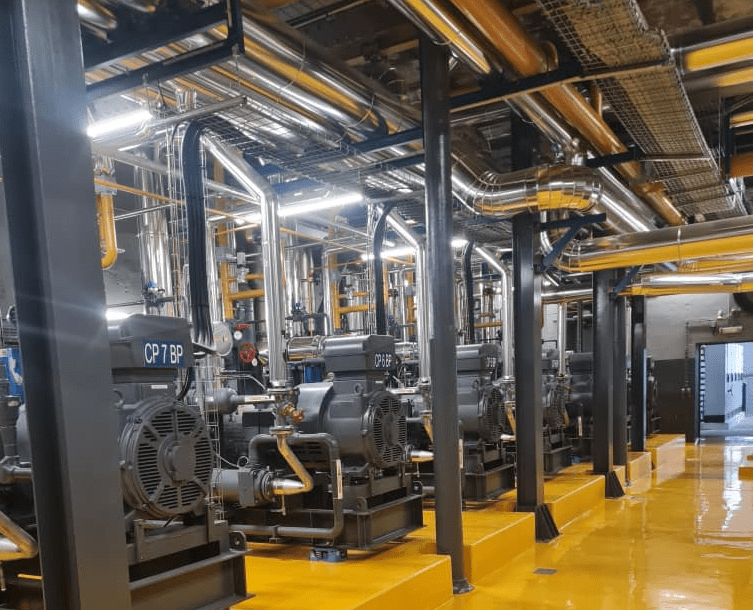

Clauger audits, designs, installs, and maintains:

- Systems for chilled water and negative glycol water production for wort cooling and fermentation,

- Compression systems using natural refrigerants (NH3, CO2, propane, etc.) for more environmentally friendly cooling production,

- Industrial hot water production solutions for brewing and boiling processes,

- Air emission treatment solutions to reduce environmental impact by turning challenges into opportunities (e.g., valorizing CO2 from fermentation, managing odor nuisances).

Clauger’s uniqueness lies in offering a comprehensive approach to industrial sites, aiming to consume the least energy possible while precisely meeting actual needs.

Thus, Clauger integrates heat recovery systems into its solutions, capturing energy from various sources to valorize available “free” energy and reuse it for other purposes within the plant. This approach helps to significantly reduce the overall energy costs of the site.

Air treatment solutions tailored to brewing and bottling processes

Thanks to its extensive experience in air treatment, Clauger is well-equipped to assist you in designing and installing efficient air treatment systems to ensure optimal environmental conditions for production processes, such as malt production.

Industrial air conditioning solutions for bottling and kegging areas are also available.

Clauger brings together multiple areas of expertise and know-how that can be tailored to your specific needs and expectations, including:

- Airflow management,

- Aerodynamic simulation of airflows,

- Industrial dust collection and ventilation, and more.

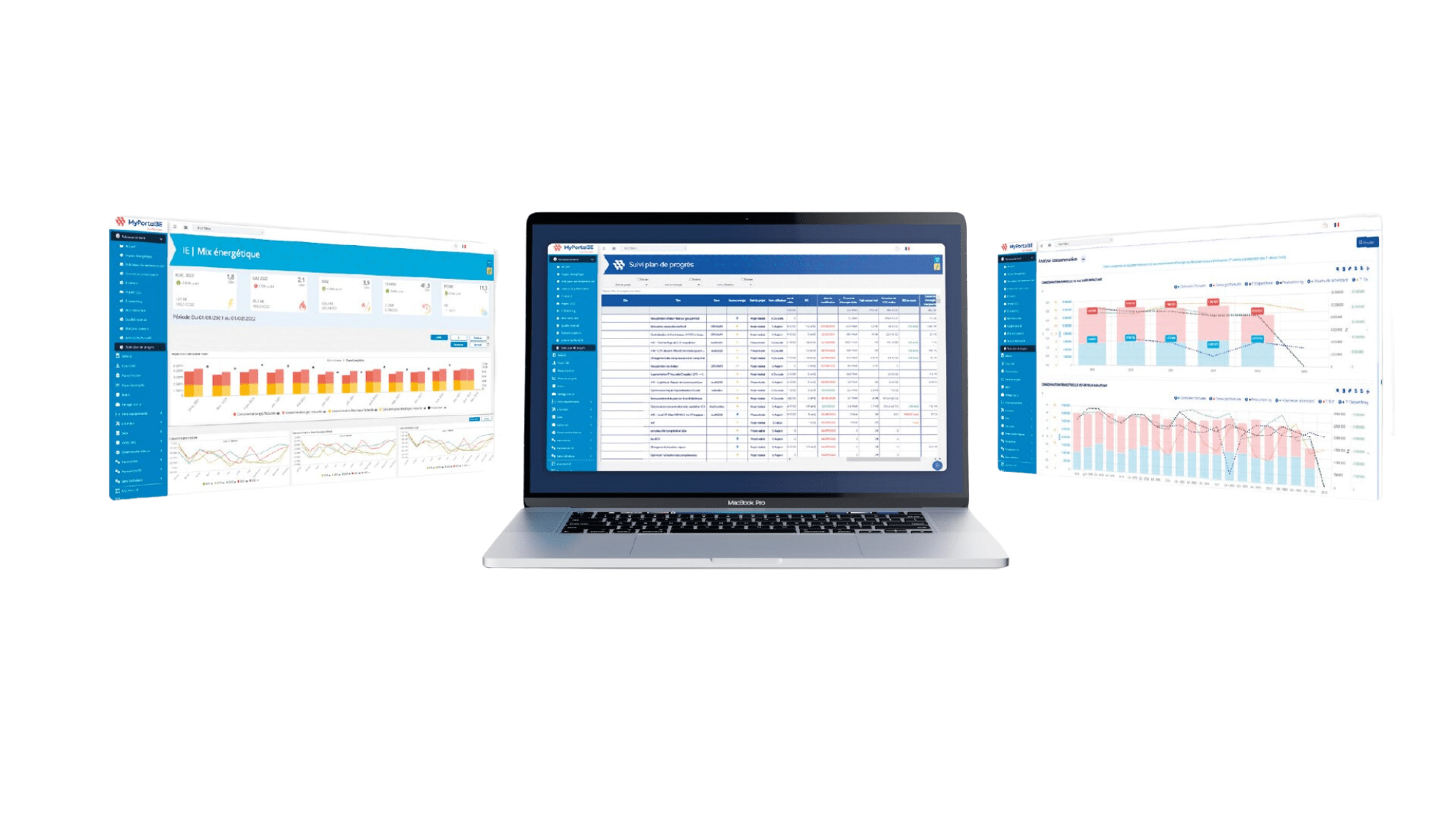

Digital innovation at the heart of your decisions

Clauger goes beyond providing high-performance energy production and air treatment solutions. We also integrate cutting-edge digital tools to ensure continuous performance.

Clauger commits to measurable performance objectives, monitored in real time through its collaborative platform, MyPortal3E, which includes:

- Real-time monitoring of your energy consumption and performance using digital twins,

- Customized improvement plans for continuous progress.

Our 360° approach also offers comprehensive project management, integrating CAPEX, OPEX, performance commitments under contract, and financing solutions.

This Clauger approach ensures breweries benefit from optimal operation of their installations, control over operating costs, and continuous improvement of their process, energy, and environmental performance.

We position ourselves as a partner dedicated to your sustainable performance.