Clauger collaborated with Emerson’s Vilter Industrial Solutions Engineering team to address the market need for improvements in performance and operational efficacy.

The Vilter and Clauger teams worked together to create an industrial heat pump application for the European market. This product innovation was driven by the increasing demand to reduce the carbon footprints of French food and beverage manufacturers.

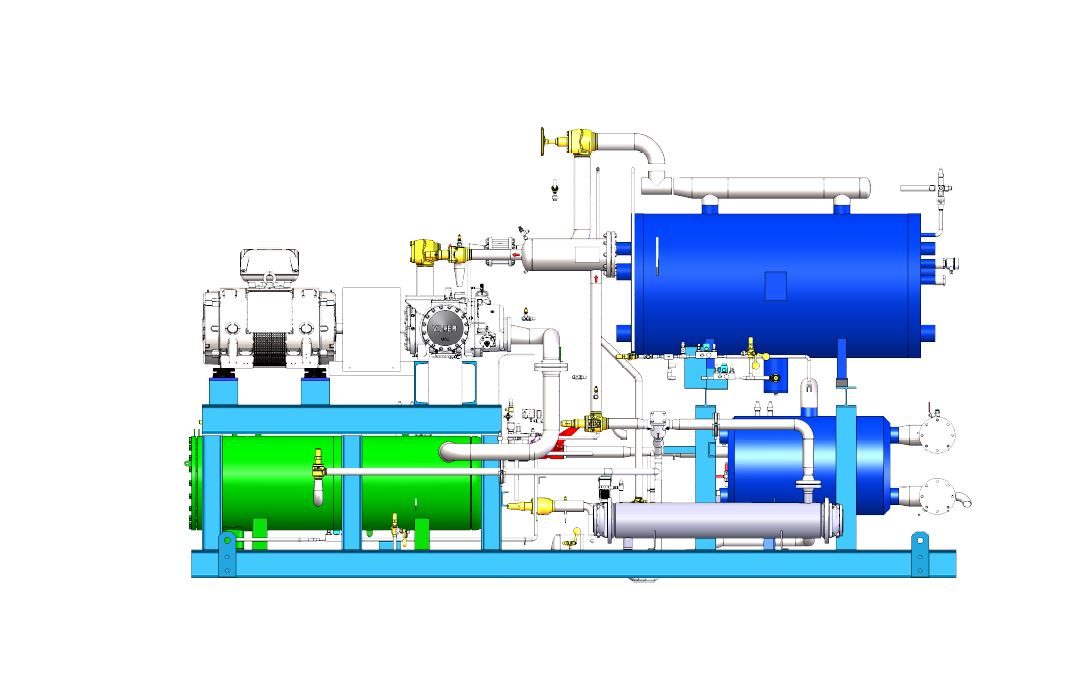

Clauger engineers, collaborating with the Emerson team, addressed the market need for improvements in performance and operational efficiency by utilizing a Vilter single-screw compressor for industrial refrigeration applications. Using ammonia, Vilter’s compressor technological solution offered Clauger a refrigerant with an environmentally conscious profile (non-ozone depleting and zero global warming impact). It also enables Clauger’s heat pump to reach higher temperatures while providing superior performance benefits in efficiency compared to competing technologies.

According to the International Energy Association, many European countries demand more energy-efficient, affordable, and sustainable technologies for their heating requirements and incentivize consumers to invest in heat pump technologies. Installing heat pumps to extract heat from water or air is increasingly popular in Europe, mainly because the heat they deliver far exceeds the energy they consume, significantly reducing reliance on fossil fuels and the need for additional renewable energy sources. For these reasons, the European Commission has designated heat pumps a renewable technology for heating and cooling.

“We are pleased to have our Vilter products be recognized as a solution to those looking for industrial heat pump solutions,” said Andy Gurney, director of EMEA sales, industrial refrigeration, Emerson. “Clauger is a valued and long-time partner, and we are honored to work with them on their industrial heat pump solutions. We are excited to help contribute to their success.”

“We chose the Vilter solution, as it had the highest coefficient of performance for the ratio of heat extracted compared to the energy consumed. We also wanted a technological solution with low annual operating and maintenance costs that uses a natural refrigerant and met our high-water temperature requirements,” said Sylvain Noël, industrial refrigeration division director, Clauger. “As Clauger constantly innovates, designs, and develops new products, the relationship between Vilter and Clauger will certainly deepen and continue to develop, particularly in relation to CO2 and gas compression over the next several months.”